Patternmaking was the exclusive business at Danko Arlington when the company started in 1920.

Today, traditional wood patternmaking has become a scarce talent.

| Craftmanship Fortunately, our skilled pattern makers have served their apprenticeships under our older generation and can compliment hand-worked craftsmanship with the latest technology. The shop uses state-of-the-art rapid prototyping FDM 3D printers to construct patterns in durable ABS or high strength Poly Carbonate plastic. In a matter of hours, patterns, core sticks and core boxes can be printed unattended in a volume up to 36”x36”x24” with accuracies of several thousandths of an inch. This exciting new and clean technology leaves our competition in the dust…literally. |

|

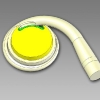

| Reverse Engineering The Pattern Division also can reverse engineer existing castings or worn patterns with our portable 7 axis CMM with a built in laser scanner. The device measures parts in the shop or in the field to an accuracy of +/- .0015 inches with +/- .0011 inches of repeatability within an 8.2 foot measuring range! |

|

| Warehouse Storage Danko Arlington also has spacious warehouse facilities to store customer patterns. Here, tooling is kept in a clean, dry, and well lighted area with locations categorized by computer for fast retrieval. |

©2025

©2025