July 1, 2024. History has a tend to repeat itself –even great ideas and technologies once invented years ago are now re-imaged, re-defined, and re-packaged with today’s technology to become even more versatile — well beyond the dreams of the earliest pioneers!

Jospeh O. Danko, Jr. was one of those pioneers. Danko Arlington’s second-generation owner and President wanted to supplement his then forty-two-year-old pattern, foundry, and machine shop business with a new and exciting technology known as ‘photogrammetry.’

After much research, in 1962, he took a giant leap from his core business and purchased a local Baltimore company founded by Harry T. Kelsh who was a brillant veteran Army cartographer in WWII and early inventor in the field of map making. The concept of photogrammetry is simple: using photographs to create accurate measurements using depth perception — similar how we see with our eyes.

At that time, the technology involved using film to take two pictures at once or ‘in-stereo,’ then project them on to a flat reference surface whereby an operator who wore 3-D glasses could focus the stereo images from different elevations to identify the contours of an image.

Mr. Danko’s new business venture became a part of the existing Maryland corporation and was known as the Kelsh Instrument Division of Danko Arlington. Mr. Danko spent almost thirty years expanding Harry Kelsh’s ideas to create more technological instruments manufactured at our existing plant in Northwest Baltimore City. The Kelsh instruments were also symbiotic because they also were made from patterns created in our pattern shop, castings made in our foundry, and machining and assembly in our machine shop. This unique diversification helped our energy dependent company survive the oil embargo and deep recession in the 1970’s by having the company workforce contribute our efforts producing Kelsh products when other business was slow.

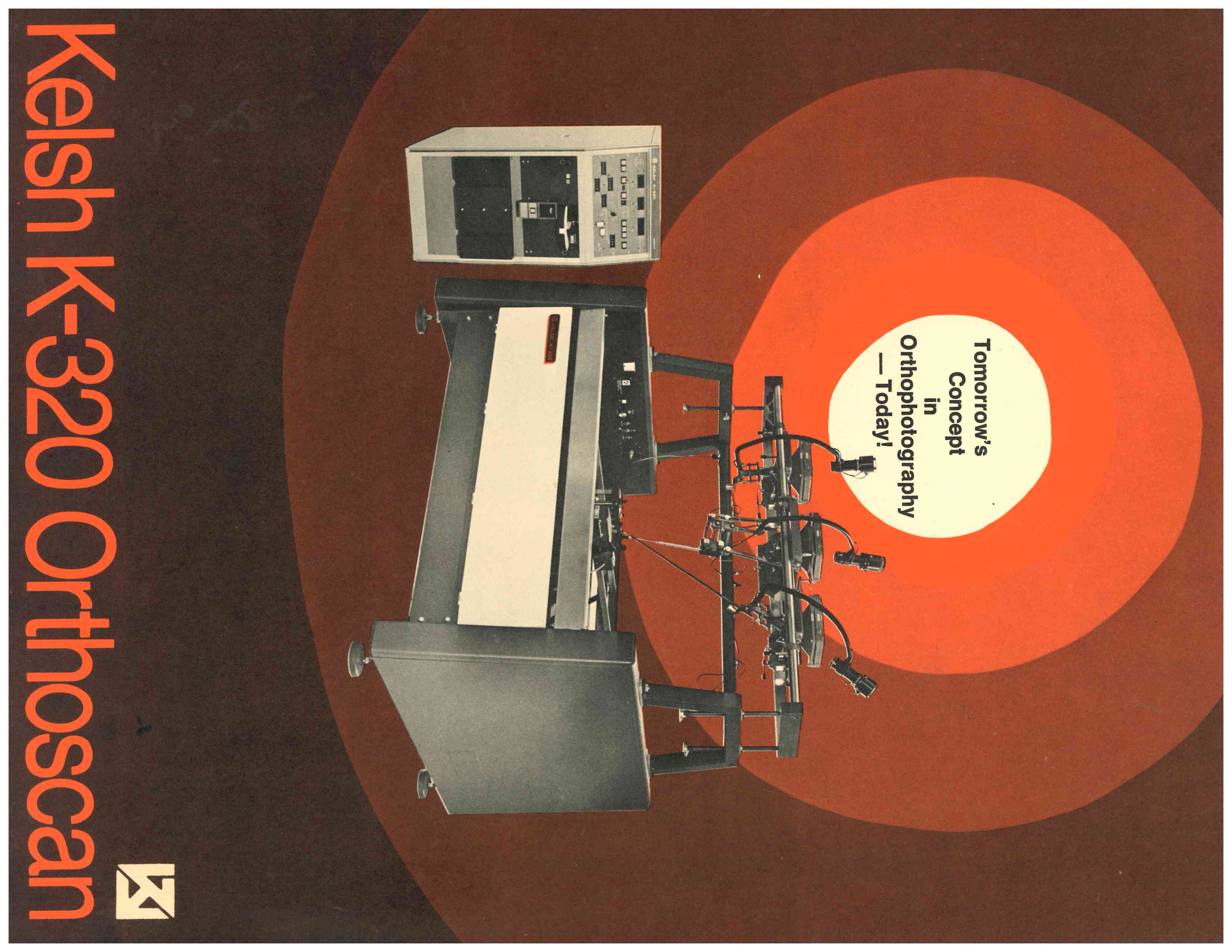

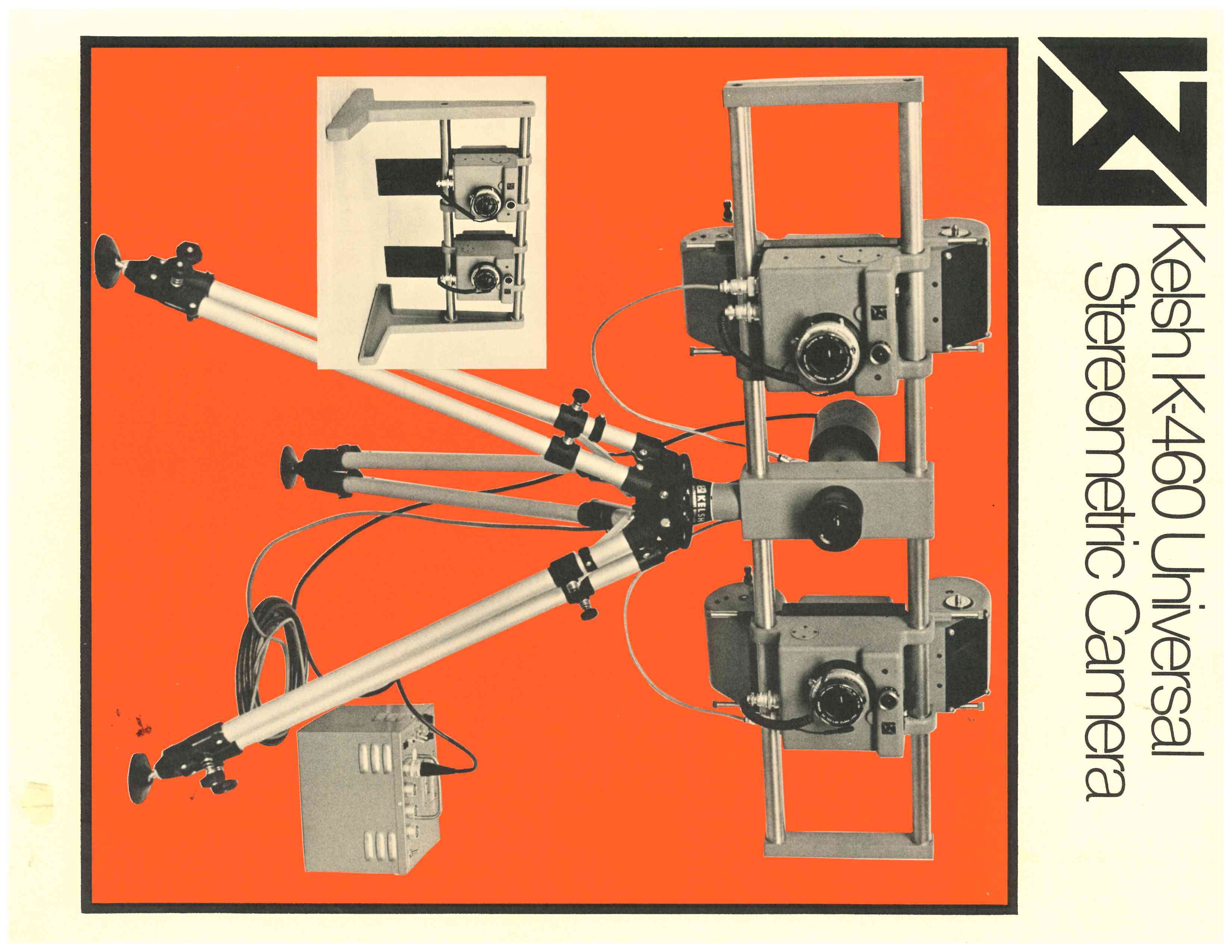

Through hours of engineering, testing, and design from the early 1960’s, Mr. Danko developed his own stereo camera which he named Model K460 and a map making plotter machine called the K320 Orthoscan. The camera used a large roll of Kodak film and was used either in an aircraft on a floor-based stationary tripod. Once the K460’s film was developed, it was then projected with the K320 to serve as template for drawing contour maps. The equipment was marketed to the US Geological Survey, Mines, Foreign Governments, map makers. Mr. Danko also tried to market his camera for early breast cancer detection in medicine to visually document potential cancerous lumps to save lives. However, few customers were willing to further invest in this archaic film process that was rapidly becoming obsolete by satellite, digital, and computer technologies.

Danko Arlington’s largest competitors were from Germany: the Leica Company from then East Germany and the Zeiss Company from West Germany. The Kelsh company eventually closed in 1980 due to the growing use of satellite technology and the advancement of the computers. Today, the whole world has accurate real-time maps at our fingertips on cell phones! Photogrammetry and laser scanning has also grown more available in industry as well.

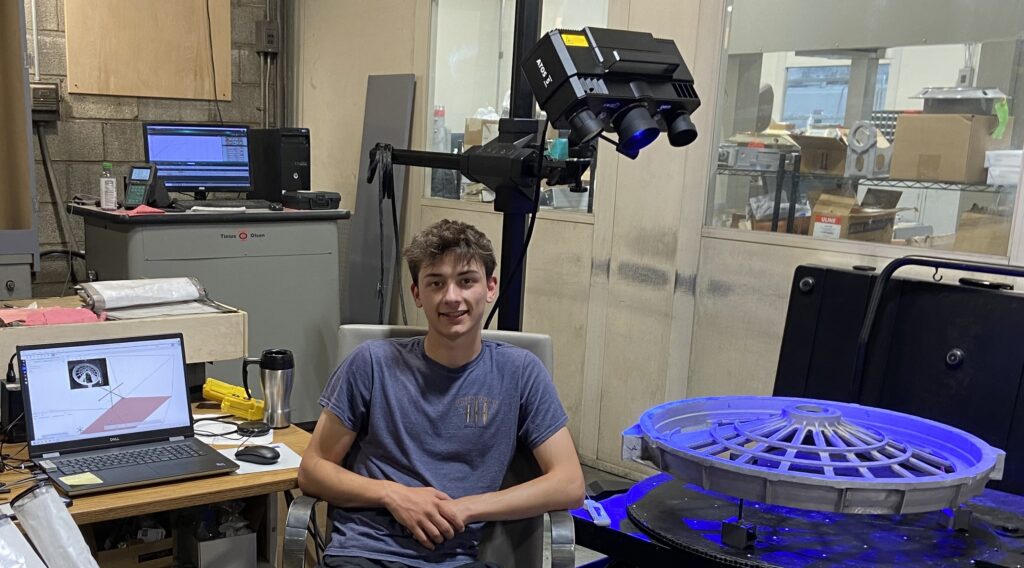

Recently, Danko Arlington purchased a Zeiss ATOS 5 photogrammetric camera with advanced Zeiss Optical Inspect 3-D software to measure and qualify our core products – aluminum and bronze sand castings. ‘ATOS’ is an acronym for ‘Advanced Topometric Optical Sensor.’ By taking pictures at different angles of an object or in our case, complex castings, the images are instantly processed by the software to produce an accurate digital copy within microns of resolution. The images then can be overlayed to a nominal CAD model for quick surface comparisons or used to verify specific drawing dimensions. This amazing process thereby makes measurements with calipers, height gages, scales, and even coordinate measuring machines (CMM’s) obsolete! This newly re-defined Industry 4.0 instrument is real time, accurate, fast, and reliable.

Over the past century, Danko Arlington’s measurements were performed by quality control personnel who have manually inspected our custom castings. With this new Industry 4.0 system, all those previous measuring methods will now be obsolete. With the new Zeiss ATOS 5 camera, Danko Arlington will be completely transformed into a new digital age!

More importantly, this new photogrammetry is absolutely necessary to replace our highly trained inspectors who have retired. Workforce is the primary challenge facing industry today. With so many experienced personnel leaving industry today, there is a huge shortage of skilled workers. Not only is the next-generation workforce not properly trained or ready to fill the gap with manual measuring methods, but they lack interest in anything not related to digital.

Therefore, the acquisition of the Zeiss ATOS 5 is indeed a gamechanger. The digital images will be automatically knitted and processed by the computer to produce a virtual part for rapid part inspection. This artificial intelligence process now takes literally seconds. Production capacity is increased with speed and accuracy that would never have happened before with manual methods. The resolution of millions of stereo pixel images is also far greater than any accuracy that we could have imagined using conventional measuring methods.

Better, more accurate parts, not only reduce scrap, shorten deliveries, and lead times, but also contribute to improved customer satisfaction. The data and metrics collected can also be used to show trends, concerns, borderline situations, and other factors which we would not have seen before. Digital copies of each part can also be stored for reference and can be particular useful for disputes to prove the castings were made correctly yet may have been setup in machining incorrectly.

The feedback from quality and inspection also assists other factory processes for tighter control or improvements. Seeing the big picture of a digital part color shaded with green or red surfaces, indicating that they are in or out of tolerance, also make it easier for better understanding what is conforming and what is not. Even the most non-technical of personnel can understand the most complex of issues from just one color surface compare picture.

Manufacturing accurate parts from the start, without scrap or rework, is a great overall benefit to the company as well. This contributes to more confident production, lower costs, and shorter build cycles. Metrics such as scrap, rework, and returns are now used to measure the success of the implementation of this project. Improvements begin almost immediately upon implementation of photogrammetric inspections.

Each custom casting produced will certainly need to be re-evaluated on a case-by-case basis. This includes tooling accuracy which, by-the-way, can also be verified with the use of photogrammetry by measuring pattern tooling, molds, reverse engineering, and first article inspections.

In addition, each finishing process will also be more closely monitored to ensure that our operators’ hand skills such as grinding and straightening are within customer drawings and specifications. It is not that we do not do this already, but the difference will be the new level of accuracy and feedback that our personnel will now receive. Within a year’s timeframe, our company should see significant improvement within our business.

In summary, this Industry 4.0 technology will radically change all aspects of our operation to make our company streamlined and more efficient. This will now be done with fewer inspectors and eliminate years of training for conventional measuring skills. The next generation of inspectors will even be able to evaluate production using a laptop computer and/or even work remotely without having to physically manipulate a casting in Danko Arlington’s inspection departments.

Worth mentioning also that it is ironic that Danko Arlington’s current CMM, Romer, and conventional manual inspection departments were previously used for the production and assembly of our Kelsh Division’s photogrammetry instruments in the 1960’s and 1970’s! Those areas are now be transformed decades later with the same but updated exciting technology — dreamed by Joseph O. Danko, Jr. to transform the existing family foundry business into something new and exciting.

Mr. Danko’s dreams of making photogrammetry practical and useful became true, albeit with his large competitor’s time and investment to perfect this field with the latest technology.

Nevertheless, Danko Arlington, Inc. was a true pioneer in this field of photogrammetry over sixty years ago and has come full circle to be a player again in 2024. No doubt, the implementation of this Industry 4.0 Technology is a ’gamechanger’ and will enhance our well-established foundry with not only the addition of photogrammetry, but with 3-D plastic and sand printing, advanced solidification finite element software, and a cloud-based ERP system for decades more of metal casting excellence. Mr. Danko would certainly be proud!

©2025

©2025